Pressed pallet block machine is designed to produce pressed pallet block. And it is very simple equipment that recycling wood wastes. Meantime, pressed pallet block machine produces pressed pallet block with high temperature and high pressure.

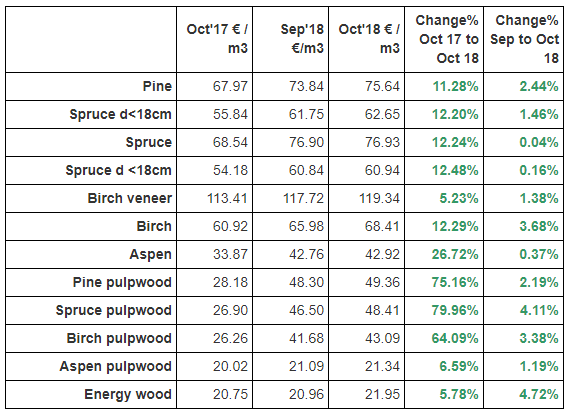

But the fact is the price of timber rises. Round wood prices in Estonia increased again in October 2018, similar to the rapid rise in prices which started at the end of 2017 and lasted until the beginning of 2018.

The price trend for pine sawlogs has once again gone up, after several months of decrease. However, the spruce price is still above the pine. Conversely, in the small-diameter segment, the price of pine is above the price of spruce. Overall, the previous price trend in 2018 is stable. Compared to the previous year, prices have risen by 11% to over 12%.

In hardwood, the birch, especially birch sawlogs, the price noticeably increased. For aspen, the rise is only minimal.

For the pulpwood assortments, all prices have risen since September, with the spruce showing the strongest growth with just over 4%, followed by the birch with 3.4% and the pine with 2.2%. The price spectrum is led by the pine with over €49/ m3, followed by spruce and birch. The price increases compared to the previous year are up to a maximum of 80%. The prices seem to settle at this level after the end of the rapid increase in spring. The price of aspen pulpwood only increased by 1.2% from September to October and, at + 6.6%, is also comparatively slightly above the previous year’s level.

If you are involved in the wooden pallet industry, you maybe have a headache about the higher and higher price. The price of timber is rising , so that it will increase your production cost of pallet blocks. But PalletMach can give you the cost-effective solution of the whole pallet block production.

PalletMach devotes oneself to to protect our environment. And we also try our best to change wood waste into treasure. Hence, we update pallet block machine, and improve the structure of new pressed pallet block machine.

Wood shavings and sawdust are the best raw materials for producing pressed pallet blocks. But all wood wastes, such as wood chips, big chips, burned forest, wood boards, branches, wood flakes, the scrap of the wood, and waste pallets, and so on, are also good raw materials for compressed pallet block machine.

Features of pressed pallet block machine

- Simple machine, and easy operation. One person could handle 3 machines.

- High efficiency. The capacity of compressed pallet block machine is 6-9 m3/day.

- Cross-section is completely vertical, reducing the previous cutting loss.

- Setting the cutting length by entering the value, fully automatic, and suitable for the specifications of pallet block.

- Saving the production cost and enhancing the process of automation.

- Pallet block machine could recycle the wood waste efficiently.

- Free fumigation. Because the pallet block is made by hot pressing, it is free fumigation.

If you want to get more information about pressed pallet block machines, please email us [email protected].