Do you have any questions about how to choose proper pallets for your business? How to build your own pallets? Do you want to recycle wood waste into treasure? PalletMach will give some guides, hoping to useful for you.

Whether or not your pallets are wooden, plastic, composite, or corrugate it is very important to understand their tolerances in specific environments and applications. Through the smallest of manual operations to the largest automated processes… each pallet provides a unique tolerance factor that should be understood by all involved in its use. Having a good understanding will ensure the product suits the processes carried out in your business to the final destination.

Key items to consider in the use of wooden pallets.

1 Safety:

Whether you are considering reusing a used pallet within your business or using a system pallet for continuous reuse, consider these key points in your decision to ensure the pallet is safe and meets the required tolerances.

No broken, loose, or severely cracked boards – Depending on your environment, broken boards and wooden splinters can be a risk for safety or product damage. This can also cause automated lines to shut down where pallet tolerances are not met.

No damaged stringers with large cracks or missing pieces from the ends – Pallets with stringer damage should not be considered structurally sound in any situation. These components form the main structure of the pallet and will not support product applications, or proper handling if severely damaged.

It is not weathered from the elements to a point of warping or weakness – Wood will oxidize over time exposed to the elements. Understanding the integrity of the pallet at this stage would be difficult for the average person. Do not consider reusing.

Has no visible protruding nails – exposed nail tips, and nail heads can cause product damage, and safety risks in the manual handling process.

Is reasonably clean especially in sensitive environments – Pallets should have no loose dirt or debris or foreign matter present. Contaminated pallets should be diguarded to ensure there is no product contamination.

2 Purchasing the correct pallet products:

Depending on your business and specific needs, items to consider to ensure the proper pallet products are used, will pay off both directly and indirectly. Cheaper is not necessarily better.

- Look for a reputable, long-standing pallet provider.

- Provide complete details on your business overview.

- Are the pallets used for in house or one-way shipping?

- Include products palletized, packaged sizes and weights.

- Are the pallets handled through automated production lines?

- What handling equipment will be used?

- What are the expected volumes required?

- What type of racking is used if pallets will be stored with the product?

- What type of environment will the pallets need to encounter?

- Are the pallets required to be ISPM15 compliant?

- Will some pallets or all be required for reuse?

Is there a better choice?

Yes, there is. You can build your own pallets, presswood pallets. And PalletMach can provide some useful guides.

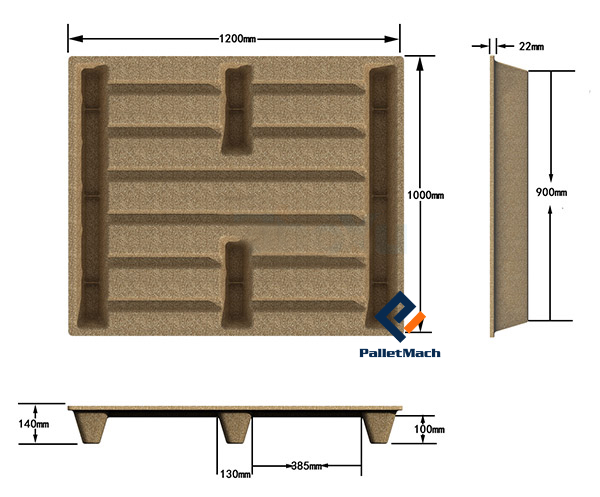

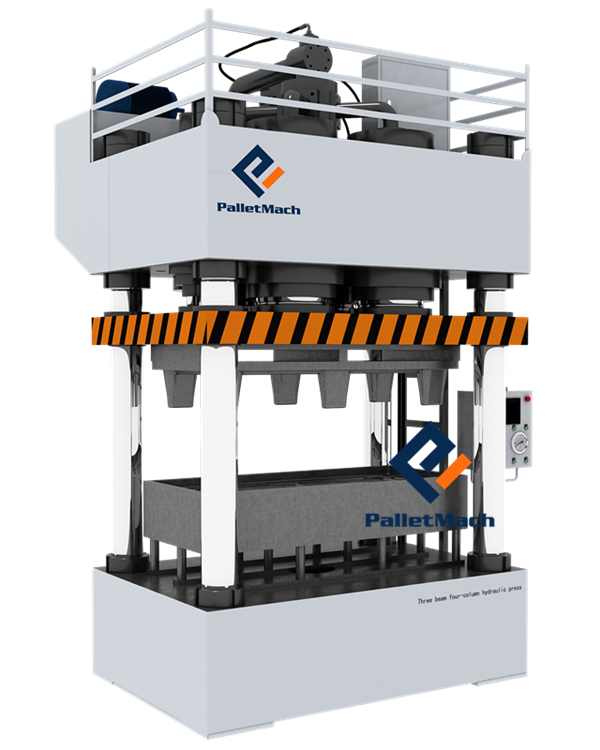

PalletMach presswood pallet machine produces presswood pallets using wood waste. And pressed wood pallet machines engage simple process flow and high efficiency. In addition, the raw materials of the machine are easy to get, which low the production cost. A lot of raw materials can be produced into presswood pallet. They are anything contains wood fiber, such as wood chips, logs, timbers, wood shavings, waste wood, waste pallet, straw, and so on. The raw material price is lower than the traditional pallet machine.

Call PalletMach and speak to one of our pallet professionals for proper guidance on the best solutions, products, and recycling programs to meet your business needs. Send an email to PalletMach [email protected]. Or you also can leave your email, we will reply you in 12 hours.