Recycling aims of wood packaging have been reduced by more than half under the latest set of proposed European Union aims.

Consequently, there is some uncertainty about the future of the UK’s confirmed wood recycling aims for 2019 and 2020 – which are set under the PRN system – and the knock-on impact on the value of wood PRNs.

The change in European thinking has come because of the strong biomass demand for waste wood and end-of-life wooden pallets, which are the main form of wood packaging waste. But, there are better perspective for wood packaging waste, which recycling them into new compressed wood pallets.

Pallets

The aims for the recycling of various packaging materials had been proposed in 2015 by the European Union. And they also were carried through to discussions last year over revisions to the Waste Framework Directive. For wood ‘preparing for reuse or recycling’, the 2015 proposals was to recycle 60% of wood packaging (usually pallets) by the end of 2025 and 75% by the end of December 2030.

But, under the latest aim proposals which were finalised, the wood recycling numbers have been hugely reduced. The much lower wood aim has now been approved by the Environment committee of the European Parliament and seems set to be approved by the UK and other member states this summer.

The new aims are for 25% and 30% in 2025 and 2030 respectively, virtually halving the previous aim rate.

Compressed wood pallets

Raw materials of compressed wood pallets are spreading all over the world, which lower the investment of compressed wood pallet project. It only can solve the problems of broken wooden pallets, but also can gain more money. At the same time, compressed wood pallet project can turn broken and waste wooden pallets into new presswood pallets.

The following are the raw materials for compressed wood pallets.

- Waste wood, scrap of the wood, sawdust wood chips, wood shaving, wood chips, big chips, raw wood, burned forest, logs, wood board, branches, timber, wood flakes, and waste pallets, and so on.

- Contenting rich fiber also can be used to produce the pallets, such as straw, waste kraft paper, bamboo, palm trees, coconut, softwood, wheat straw, bagasse, and miscanthus, and so on.

| Wood packaging recycling | |||

| 2020 | 2025 | 2030 | |

| Original proposed aims | 15% | 60% | 75% |

| Latest proposed aims | 15% | 25% | 30% |

| UK aims | 48% | TBC | TBC |

From an EU perspective, the new (lower) targets are seen as representing a doubling of the current aim for recycling of wood packaging which stands at 15%. Many countries the preferred path for wood packaging is to reuse the pallets multiple times, and then recover the energy contained in the wood from the end-of-life wood pallets.

Motivation

Nevertheless, the Commission is thought to hope that the increase in the wood packaging recycling aims. Even though they are more modest than the levels originally proposed, together with ambitious overall aims for the recycling of all packaging. And it also will create a new impetus to increase recycling of wooden packaging waste. Meantime, there are member states which are achieving high recycling levels of 70-80% for wood packaging waste, in particular by using the waste stream in the production of particle board and so saving energy and other resources.

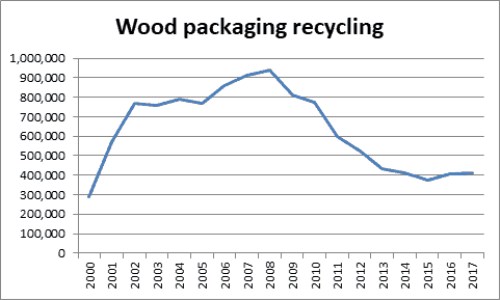

Wood packaging recycling in the UK reached as high as 900,000 tonnes 10 years ago, but with the closure of one panelboard plant and other pressures the amount has fallen to 400,000 tonnes per annum

It will be aware that the UK is now already actually meeting the wood recycling aims. However, it will also need to set the UK aims at a rate sufficient to ensure the value of the wood PRN is high enough to ensure that too much packaging wood. There are a number of new plants due to investing compressed wood pallet project. It is a major user of good quality recycled wood such as pallets) there is strong concern that wood is going to presswood pallets.

Packaging

Aims for all materials, and which are expected to be agreed, are shown below.

| Specific aims for packaging | ||

| By 2025 | By 2030 | |

| All packaging | 65% | 70% |

| Plastic | 50% | 55% |

| Wood | 25% | 30% |

| Ferrous metals | 70% | 80% |

| Aluminium | 50% | 60% |

| Glass | 70% | 75% |

| Paper and cardboard | 75% | 85% |

From the table it can be seen how the wood recycling aims are significantly lower than those for other materials.

Characteristics of compressed wood pallets

- Low moisture content and constant intensity and rigidity. Compressed wood pallet is non-hygroscopic and no deformation in the course.

- Stable dimension and no distortion and warping.

- High precision size and light weight. It is specifically designed reinforcing rib that ensures the intensity and production accuracy.

- Rounded design to prevent goods damage in the packaging and transportation process.

- Stacking type. A lot of pallets can be stacked together and the height of the 50 pieces of pallets is about 2.37 meters.

- Free fumigation and popular in the import and export transportation.

PalletMach is the leading manufacturer of compressed wood pallet machine, with more than 15 years’ production experience. If you want to get more information, please email us [email protected].