Wood pallet making machine is our featured product, which meets the requirement of environmental protection. The compressed wood pallet has been widely used in storage and transportation industries, which greatly improve the work efficiency.

- Power: 18.5 kW

- Capacity: 160-180 pieces/24 hours

- Density: 850-950 kg/m3

- Weight: 22 tons

- Warranty: 1 year

[email protected] +86-21-80392223 palletmach

Description of wood pallet making machine

1. Wood pallet making machine is a new type of one time forming machine, and is also called wood pallet machine, wood pallet molding machine.

2. Raw materials suitable for pallet machine can be waste wood and scrap of the wood, bamboo, straw, waste kraftpaper and so on.

3. Compressed wood pallet making machine is the ideal equipment for wood recycling.

How does wood pallet making machine work?

You can choose material filling method (automatic or manual) according to your need.

Core Technology

- We adopt the three-beam four-column guide device structure, which solved the problems of guide instability and the deformation of framework.

- PalletMach abandons the assembled framework hydraulic old traditional press machine, because for a long term using, the problems of guide instability in process of pressing.

- We adopt the design of crossbeam, which solved the problem of press inaccuracy of the upper and the lower mold. So it settled the inaccurate pressing of the upper mold and lower mold and deformation of framework.

- We adopt a new appearance design just to match the new revolution pressing machine.

Wood pallet machine structure features

- Detachable delivery and installation

- Customized mould

- Fully automatic production

- Protection device

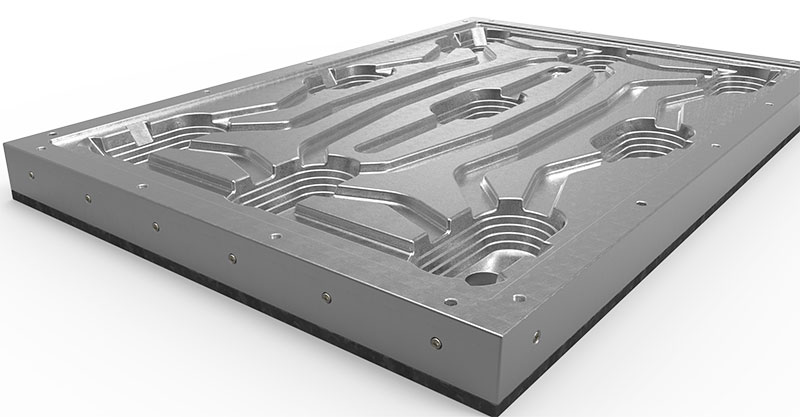

Mould of wood pallet making machine

1. The mould is engraved by a whole high strength thick steel plate with strong resistance to high temperature and high pressure. So it has higher strength.

2. Drilled inside the steel plate, the heat conduction oil way is well-distributed conduction performance, which completely solved the problem of welded oil circuit spilling.

3. All oil circuits are sealed by removable plugs, and are easy to maintain and dredge, which will longer the service life of the mould.

4. Perfect stiffener ribs design makes final pallets with light weight and high strength.

Compressed Wood Pallet

Specification:

400 mm×600 mm, 600 mm×800 mm, 800 mm×1000 mm,

800 mm×1200 mm,1000 mm×1200 mm,1100 mm×1100 mm

Pallet weight varies from 10 kg~22 kg.

Loading capacity:2~3 tons(dynamic load) and 6~8 tons(static load)

What materials can make compressed wood pallet?

Wood pallet making machine model parameter

|

Wood pallet making machine |

||

|

Model |

PM 1000 |

PM 1200 |

|

Pressure |

0--1000 tons (adjustable) |

1000--1200 tons (adjustable) |

|

Hydraulic oil cylinder quantity |

4 |

4 |

|

Pallet density |

850 kg/m3 |

850-950 kg/m3 |

|

Shaping cycle |

450 seconds |

450 seconds |

|

Pressure increasing time |

350 seconds |

350 seconds |

|

Capacity |

160 pieces/ 24 hours |

180 pieces/ 24 hours |

|

Power |

18.5 kW |

18.5 kW |

|

Weight |

22 tons |

22 tons |

If you are interested in our wood pallet making machine,,or you can build a wood pallet production line. Now continue reading!

wood pallet production line

Wood pallet production line process

- Step 1: gather the materials containing wood fiber and eliminate the impurities.

- Step 2: crush the materials containing wood fiber.

- Step 3: dry the crushed materials to 5% moisture content.

- Step 4: evenly mix the dried materials with glue according to a certain proportion.

- Step 5: fill the mixed materials into the mould and press.

- Step 6: keep pressing for about 7 minutes.

- Step 7: automatically discharge the final pressed wood pallet.

Remarks:

- The materials containing the wood fiber mentioned above refer to bagasse, bamboo, wasted wood timber, short lumber, straw and so on.

- Anything containing wooden fiber could be used as the raw materials. So the wide sources of raw materials save the manufacturing costs of wood pallet to a great extent.

- To guarantee the mixture performance of materials and glue, the moisture content should remain 5% after drying in step 3.

- The adhesive mentioned above is urea formaldehyde glue or others.

- In practical use, the measurement of pallet performance depends on the static loading and dynamic loading.

Thanks for reading. If you have any questions, you can email us: [email protected] or with our sales manager, else you can leave a message to us. Waiting for your email.